A warehouse holds multiple activities every day, where workers move through aisles, forklifts lift heavy loads, trucks deliver goods, and items move in and out constantly, making organisation and flow crucial for smooth flow and efficiency. Poor planning leads to crowding, delays, and safety risks. This is why well-designed Racking Solutions offer significant value, providing structure, height, strength, and clarity to every warehouse operation.

Every warehouse performs better when systems for receiving, picking, packing, and shipping work together smoothly, as this ensures a clear flow of goods and reduces the risk of mistakes, damage, and accidents. This article explores practical ways to improve warehouse storage, optimise flow, enhance safety, and plan layouts effectively. It provides detailed insight for warehouse owners who wish to create a long-lasting, safe, and efficient storage system.

What Is Warehouse Storage?

Warehouse storage means placing goods where workers can access them quickly and without disrupting operations. Storage improves when height, depth, and lanes are used properly.. Many warehouses focus only on floor space, which limits long-term efficiency. Utilising vertical space enables businesses to expand storage capacity without increasing the building’s footprint. Racking solutions maximise space upwards and create additional levels for organisation and operational efficiency.

Storage systems should also consider:

- The dimensions and weight of products

- The type of pallets used

- Equipment required to lift and move items

- The width of aisles for forklift and worker movement

- Frequency of access needed for each item

A warehouse that respects these factors achieves higher efficiency, safer operations, and smoother workflow for daily activities.

Importance Of A Pallet Racking System

A pallet racking system provides elevated storage that allows goods to rest above the floor, leaving space for forklifts and workers to move freely. These systems provide strength, stability, and organisation for warehouses of all sizes, helping to keep aisles open, reducing congestion, and preventing damage to goods.

Pallet racking is suitable for a wide range of industries, including:

- Retail warehouses for fast-moving consumer goods.

- Food and beverage storage that requires quick access and rotation.

- Wholesale distribution centres with large volumes of products.

- Construction suppliers storing heavy materials.

- Manufacturing warehouses with bulk components.

A good pallet racking system also incorporates safety measures such as:

- Mesh decking to prevent small items from falling

- Load signs to indicate maximum weight limits

- Safety bars to prevent beam movement

- Upright protectors to reduce forklift impact

With these features, pallet racking systems support a safer, more efficient, and orderly storage environment, ensuring that workers can perform their tasks without unnecessary stress or risk.

Industrial Racking Systems For Heavy-Duty Warehouses

Warehouses storing heavy, long, or unusually shaped goods require industrial racking systems, which are built with reinforced uprights, wide beams, strong bracing, and anchored flooring for maximum stability. These systems provide support for goods that require high strength and consistent performance over long periods.

Industries that benefit from industrial racking include:

- Automotive parts warehouses storing engines, tyres, and accessories

- Steel and metal supply businesses handling pipes, sheets, and rods

- Timber yards and construction materials storage

- Manufacturing facilities with bulk components and machinery

Industrial racking systems ensure that heavy loads remain stable and secure, reducing the likelihood of accidents and product damage. Each upright, beam, and anchor is designed to withstand heavy loads without bending, while maintaining clear visibility and access for workers to retrieve items efficiently. A well-installed industrial rack system provides long-term reliability and peace of mind for both warehouse managers and staff.

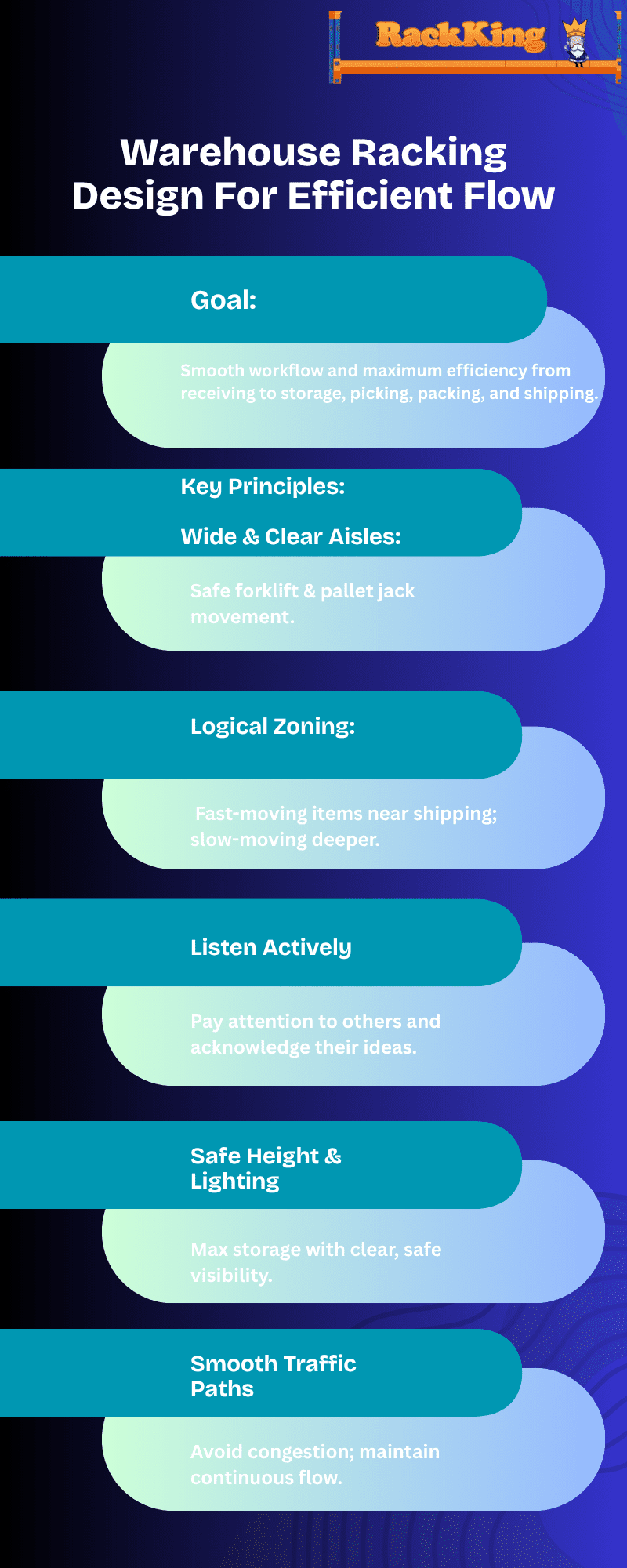

Warehouse Racking Design For Efficient Flow

Warehouse racking design determines how aisles, rows, zones, and shelves are arranged to create a smooth workflow and maximise operational efficiency. A well-designed layout allows goods to move seamlessly from receiving to storage, picking, packing, and shipping without creating congestion or delays.

Effective warehouse racking design considers:

Wide and clear aisles: Forklifts and pallet jacks require sufficient room to operate safely without scraping racks or creating hazards.

Logical zoning: Items with high turnover should be stored near picking and shipping areas, while slower-moving goods are positioned deeper in the warehouse.

Safe height and lighting: Tall racks increase storage capacity, but proper lighting ensures that workers can see clearly and safely access goods at all levels.

Smooth traffic paths: Entry, exit, and internal flow must be designed to avoid collisions between incoming and outgoing goods, maintaining continuous movement throughout the warehouse.

A well-planned warehouse layout not only improves operational efficiency but also contributes to worker satisfaction by providing a clear, organised, and safe environment.

Warehouse Racking Design for Efficient Flow

Optimising Receiving, Picking, Packing, And Shipping

The flow of a warehouse relies heavily on the efficiency of receiving, picking, packing, and shipping processes. Receiving is the first step, where goods arrive from suppliers and are checked for accuracy, quality, and quantity. Proper placement during receipt ensures that items are moved quickly into storage without blocking aisles or disrupting other operations.

After receiving, goods move to storage areas, where racks and shelving provide organised placement. Workers must be able to find and access items quickly, supported by clear labelling and logical rack arrangements. Picking operations benefit greatly from systematic storage and rack organisation, allowing staff to follow smooth pathways and retrieve items in sequence without backtracking or creating congestion.

Packing requires a designated space where workers can efficiently prepare goods for shipping. Tables, open space, and clear organisation help workers avoid mistakes while handling multiple orders simultaneously. Shipping involves the final movement of goods to delivery vehicles, where properly planned lanes prevent cross-traffic and delays.

When these four stages operate together harmoniously, the warehouse experiences improved flow, reduced errors, enhanced safety, and higher overall productivity.

Expanding Vertically With Mezzanine Floors

When warehouse floor space reaches its limit, vertical expansion provides a strategic solution. A mezzanine adds an extra level without expanding the building.. This method enables warehouses to add capacity for storage, packing, sorting, or office space while maintaining clear ground-level movement.

Mezzanine floors offer multiple advantages:

- Additional storage space for slow-moving or seasonal goods

- Dedicated packing and sorting zones that improve workflow

- Office areas for administration without disrupting warehouse operations

- Efficient use of high ceiling space that would otherwise remain unused

Safety is a critical aspect of mezzanine floor design. Guardrails, staircases, and gates must comply with building codes, while floors must be able to support the combined weight of goods, machinery, and workers. Proper installation ensures long-lasting performance and enhances overall warehouse efficiency.

Prioritising Safety Throughout Warehouse Operations

Safety is the foundation of every warehouse operation. Heavy loads, moving equipment, and busy workers create inherent risks that must be addressed through careful planning and strong racking solutions.

Key safety measures include:

- Adhering to load limits on racks to prevent bending or collapse

- Installing rack protectors to reduce damage from forklifts

- Using clear signage to communicate load restrictions and safety instructions

- Conducting frequent inspections to identify wear, rust, or structural issues

- Ensuring all walkways and aisles remain free from obstruction

Scheduling Racking Audits For Expert Insight

Even well-organised warehouses benefit from professional audits, as expert advice ensures that racking systems, layouts, and operational procedures remain optimised. A racking audit evaluates:

- Rack frame integrity and beam strength

- Anchor and floor stability

- Aisle widths and layout efficiency

- Weight distribution and load capacity

- Compliance with safety standards

Audits provide actionable recommendations that improve efficiency, reduce risk, and extend the lifespan of storage systems. For reliable professional audits in Australia, many warehouse operators rely on Rack King Australia, which offers experienced guidance, industry-standard inspections, and effective racking solutions.

Long-Term Storage Solutions For Efficiency

Creating lasting storage solutions involves combining robust racking, clear layout design, efficient workflow, and ongoing maintenance. Effective solutions enable warehouses to maintain high levels of efficiency while reducing operational stress and improving worker productivity.

Benefits of long-term storage solutions include:

- Reduced risk of accidents and product damage

- Faster and more accurate picking and packing operations

- Improved organisation and visibility of goods

- Simplified staff training and orientation

- Enhanced operational control and reliability

When storage solutions are designed with foresight and maintained properly, warehouses experience smooth operations, safer environments, and stronger business performance over time.

Conclusion:

A warehouse achieves long-term success when storage, flow, safety, and vertical expansion work together cohesively. Racking Solutions form the backbone of a productive environment, supporting receiving, picking, packing, and shipping while ensuring safety and operational efficiency.

Properly designed racks, industrial systems, and mezzanine floors maximise space, enhance workflow, and protect workers, while expert audits provide clarity and guidance for improvement.

Reading Recommendations:

Australian Pallet Racking Standards Guidelines AS 4084

Multi-Level Mezzanine Design and Installation in Australia: A Complete Guide.

FAQs

What do Racking Solutions provide for warehouses?

Racking Solutions offer structure, order, height, and stability, which helps workers move efficiently and ensures that goods are stored safely and accessibly.

How does a pallet racking system improve warehouse storage?

A pallet racking system elevates pallets above the floor, creating additional space and organised rows, which increases efficiency and reduces congestion.

Why is warehouse racking design important?

Warehouse racking design determines the layout of aisles, zones, and storage levels, reducing travel time, improving picking accuracy, and ensuring smooth workflow.

What is the value of a racking audit?

A racking audit identifies weaknesses in structure and layout, improves safety compliance, enhances efficiency, and provides actionable recommendations for long-term improvement.