Warehouse space optimisation is no longer a nice extra. For Australian industrial operators, it directly affects margins, safety, and long-term growth. Land and construction costs continue to rise, especially in major logistics corridors. Expanding your footprint is expensive and often slow due to approvals and compliance requirements. That is why more facility managers are focusing on smarter warehouse storage solutions rather than bigger buildings.

By improving layout design, racking systems, and inventory placement, you can unlock unused cubic capacity already sitting above your head. When done properly, warehouse space optimisation improves flow, lifts throughput, and strengthens safety without major structural changes.

This guide draws on current Australian standards, Australian government guidance, and Australian industry research to outline practical, evidence-based strategies you can apply in your own facility.

What is Warehouse Space Optimisation?

Warehouse space optimisation is the structured process of maximising usable cubic volume while maintaining safe, efficient material handling flow. It goes beyond adding extra racking. It involves:

- Reviewing your warehouse racking layout guide principles

- Analysing warehouse slotting optimisation

- Improving storage density without blocking access

- Aligning layout with warehouse throughput improvement goals

At its core, optimisation means balancing three factors: storage capacity, accessibility, and operational efficiency. You are not just filling space. You are designing a system that supports faster picking, smoother replenishment, and safer movement.

According to Safe Work Australia’s guidance on warehousing risks, poor layout design increases collision, collapse, and manual handling hazards. That is why optimisation must integrate safety from the start.

Storage optimisation shows how Australian warehouses make the most of space while handling more products. In simple terms, warehouse space optimisation is about designing your warehouse storage solutions to work harder, not just bigger.

Benefits of Optimising Your Warehouse Space

Lower Operational Costs

Building extensions or renting off-site space adds rent, transport, labour, and insurance costs. The Australian Bureau of Statistics continues to report rising non-residential construction costs across industrial sectors. By improving warehouse capacity planning and maximising warehouse space internally, you defer capital expenditure.

High-density storage racking, mezzanine storage systems, and vertical storage systems often deliver a faster return than expansion.

Increased Picking Efficiency

When you optimise warehouse slotting and reduce unnecessary travel distance, picking times drop. Australian industry research and guidance from Safe Work Australia and state regulators consistently highlight travel distance as a major contributor to manual handling risk and labour inefficiency.

Placing high-velocity SKUs closer to dispatch areas improves warehouse operational efficiency and supports faster order fulfilment. Racking solutions also improve aisle clarity and reduce congestion, directly influencing throughput.

Improved Safety and Compliance

In Australia, pallet racking systems must comply with AS 4084-2023, the recognised Australian pallet racking standards. Standards Australia outlines design, installation, and load requirements to reduce collapse risks.

Clear aisles, defined pedestrian zones, and compliant industrial racking systems reduce incident risk. This aligns with Safe Work NSW and Safe Work Australia recommendations for preventing struck-by and crush injuries.

Enhanced Scalability

An industrial mezzanine system or multi-tier shelving system allows you to accommodate more SKUs without expanding the warehouse footprint. This is particularly valuable for growing e-commerce and spare parts operations.

Warehouse space optimisation provides a scalable foundation. You can add levels, adjust layouts, and integrate new technology without major structural work.

How to Calculate Your Current Space Utilisation

Before investing in new racking systems or redesigning your warehouse layout, it’s essential to understand how efficiently your current space is being used. Accurate data prevents overinvestment and ensures your storage areas perform optimally. The following steps break down the process:

| Step | Action | How to Measure | Example / Notes |

| 1 | Calculate Total Storage Volume | Multiply internal floor area (m²) by clear internal height (m) | 2,000 m² × 8 m = 16,000 m³ total theoretical volume. This is the maximum space you could potentially use. |

| 2 | Determine Actual Occupied Volume | Estimate the volume taken by stored goods and racking footprint, including: • Pallet loads (L × W × H) • Mezzanine storage platforms • Bulk storage areas | If stored goods occupy 4,000 m³ in a 16,000 m³ building → Utilisation = 25%. Australian benchmarks suggest 22–27% as a healthy utilisation range. |

| 3 | Identify Underutilised Zones | Look for: • Excess vertical clearance above pallets • Aisles wider than required for current forklifts • Dead corners or inefficient rack layouts • Obsolete inventory blocking prime locations | Safe Work Australia notes that unused vertical space is the largest opportunity to increase storage density. Adding or redesigning a mezzanine floor can free thousands of extra cubic metres. |

By following these steps, you can quickly pinpoint where your warehouse is underperforming and identify opportunities to increase storage capacity without expanding the building footprint. Regular space utilisation reviews ensure that racking, aisles, and storage zones are optimised for both safety and efficiency.

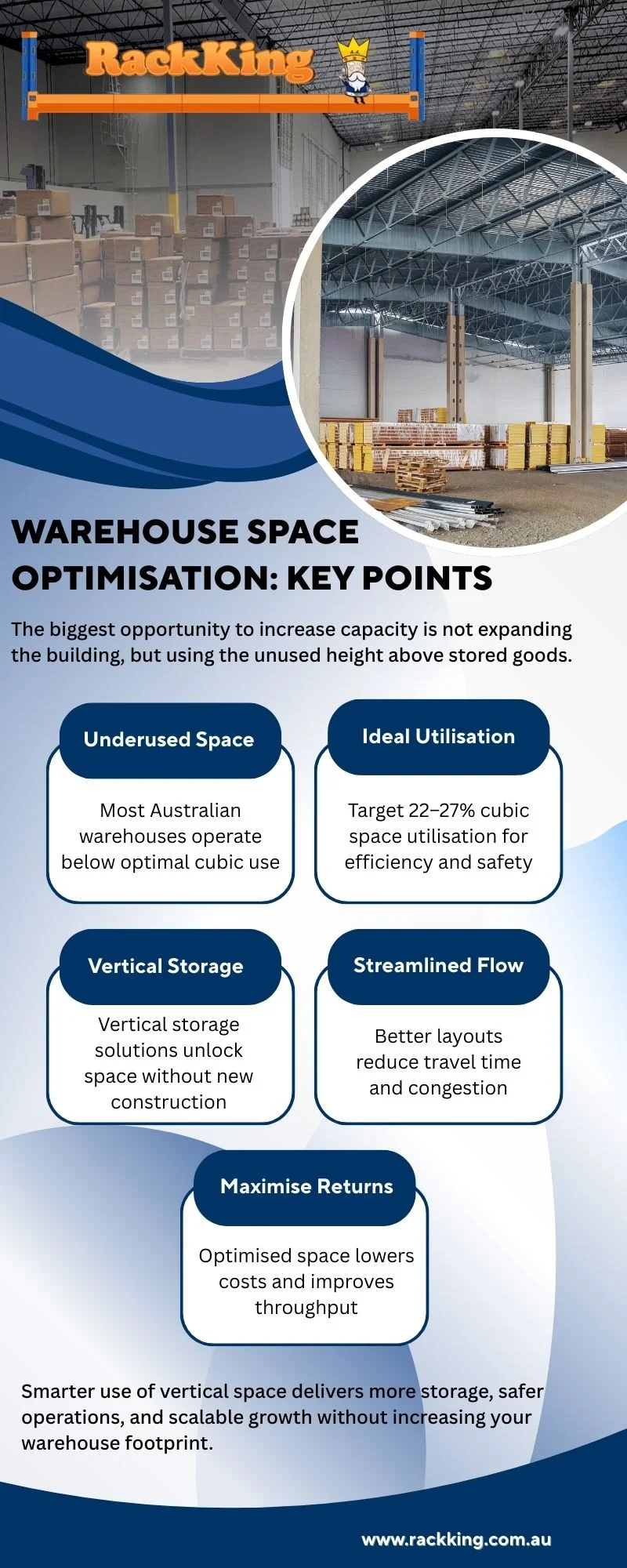

Warehouse Space Optimisation: Key Points

Practical Storage Strategies for Industrial Facilities

Utilise Vertical Real Estate

Most warehouses use less than their full height. Installing a warehouse mezzanine system or industrial mezzanine system effectively creates a second floor. Multi-tier shelving systems are ideal for small parts.

For palletised goods, heavy-duty pallet racking systems can extend closer to roof height, subject to engineering limits and fire regulations. When dealing with higher load ratings, reference Australian engineering and compliance requirements.

Adjust Aisle Widths

Transitioning from conventional wide aisles to narrow aisle racking reduces wasted floor space. However, reducing aisle width may require new forklifts.

WorkSafe Victoria highlights the importance of matching plant and equipment to layout design to prevent collision risks. A careful material handling flow assessment is essential before narrowing aisles.

Implement Double-Deep or High-Density Racking

Double-deep pallet racking stores pallets two-deep instead of one. High-density systems, such as drive-in or mobile pallet racking, increase storage density. These systems support warehouse expansion alternatives without new construction. Proper engineering and Pallet racking installation are critical to ensure compliance and structural integrity.

Deploy Cross-Docking

Cross-docking reduces the need for long-term storage by moving goods directly from receiving to shipping. Australian transport and logistics guidance published through federal and state freight strategy frameworks recognises cross-docking as an effective method for reducing storage footprint when demand is predictable.

Advanced Inventory Management Techniques

ABC Slotting Analysis

ABC analysis ranks products by velocity and value. High-frequency “A” items should sit in the most accessible zones near dispatch.

Australian procurement and inventory guidance used across public and private sectors recognises ABC classification as a core inventory control strategy. When applied to warehouse slotting optimisation, it reduces travel distance and improves picking accuracy.

Dynamic Slotting

Dynamic slotting adjusts locations based on seasonality or real-time demand. This supports scalable warehouse storage solutions in fast-changing environments.

The 5S Methodology

Sort, Set in Order, Shine, Standardise, Sustain.

These lean warehouse management principles reduce clutter and free up usable storage zones. Safe Work Australia reinforces that orderly workplaces reduce incident risk and improve compliance.

Regular audits and warehouse inspections are essential to keep racks safe and in good condition.

Role of Technology in Space Optimisation

Warehouse Management Systems (WMS)

A WMS provides real-time visibility into stock levels, slotting efficiency, and cube utilisation. According to Safe Work Australia and Austrade logistics guidance, digital integration improves operational visibility, resource allocation, and overall warehouse efficiency. With accurate data, warehouse reorganisation strategies become evidence-based rather than reactive.

Automated Storage and Retrieval Systems (AS/RS)

AS/RS enables high-density vertical storage beyond safe human picking heights. Robotics and shuttle systems reduce aisle requirements and increase storage density. When integrating automation, compliance with AS 4084-2023 and Australian engineering requirements remains mandatory.

Conclusion

Warehouse space optimisation is about smart planning, not just adding more racks. By assessing cubic space utilisation, improving your warehouse layout, and applying targeted storage strategies, you can increase capacity without expanding your building.

For Australian operators, following safety regulations, engineering standards, and proper installation practices is essential. When optimisation combines lean warehouse management with data-driven planning, you get lower operating costs, faster picking and dispatch, safer working environments, and scalable growth for future needs

If your warehouse feels cramped, the answer may not be more space; it may be better warehouse space management. For expert guidance and professional installation, contact RackKing to make your storage systems work harder and safer.

FAQs

What is the ideal warehouse space utilisation percentage?

Industry benchmarks used across Australian warehousing frameworks commonly cite 22–27 per cent of total cubic volume as a healthy range. Pushing significantly beyond this often increases congestion and reduces picking efficiency.

Can a mezzanine floor be installed without major construction?

In many cases, yes. Modular industrial mezzanine systems are freestanding steel structures. However, compliance with the National Construction Code and local approvals may apply.

How do I identify obsolete stock taking up space?

Use inventory ageing reports within your WMS. ABC analysis helps flag slow-moving items. Australian procurement guidance recommends periodic reviews to prevent excess holding costs.

Does reducing aisle width require new forklifts?

Often, yes. Very narrow aisle layouts typically require specialised equipment. WorkSafe Victoria advises ensuring equipment suits the operating environment.

What are the best racking systems for small parts storage?

Multi-tier shelving systems and mezzanine storage systems are commonly used for small parts. They maximise vertical storage systems while maintaining accessibility.