Racking plays a key role in any warehouse. Not only does it keep heavy goods secure, but it also creates a cleaner, safer, and less stressful working environment. With smart shelving, workers can easily navigate from one shelf to another, reducing retrieval time, minimizing mistakes, and reducing fatigue.

A well-designed rack system keeps goods raised and properly supported, protecting inventory from damage caused by floor moisture, pests, or accidental collisions. Studies show that vertical rack systems can increase storage capacity by up to 30% compared with ground-level stacking. Explore this article for more safe and secure warehouse racking.

Main Types Of Warehouse Racking Systems

Australia employs a variety of different types and sizes of warehouse shelving systems. They each have different strengths to help solve different kinds and levels of storage issues.

Selective Pallet Racking

In many warehouses, the system of choice is selective pallet racking. This allows workers to have direct access to all shelves and pallets, making it much easier for them to load and unload items. It is suitable for use with many different forklifts.

Drive-In Pallet Racking

Drive-in pallet shelving is used in large warehouses that store a large number of pallets. With this type of racking, the forklifts enter directly into the racking system to load the products far behind their front positions. This saves space on the floor and allows a much higher density storage than other systems.

Double-Deep Racking Systems

It is possible to increase storage space by using double-deep pallets. This will allow for more room in your warehouse, without adding additional aisles. If you need a warehouse that maintains even storage density, this is the solution.

Cantilever Racking Australia

Cantilever racking is widely used in Australia by businesses. It’s a great system for handling tall, large, awkward, or irregular items.

Mezzanine Racking Systems

Storage warehouses can add a 2nd or 3rd level without needing an expensive extension. Mezzanine systems can be designed with varying levels of support, ranging from heavy to light loads.

Push-Back Racking Systems

Push-back racking is ideal for warehouses that need high-density storage without sacrificing speed. In this system, pallets sit on wheeled carts that slide along inclined rails. When a new pallet is loaded, it gently pushes the previous one backward.

Pallet Flow (Gravity Flow) Racking

Pallet flow is a system that uses sloping roller tracks and gravity to advance pallets. Employees load pallets on the back of the truck and remove them in the forward direction, using a “first-in-first-out” pattern.

Mobile Racking Systems

Mobile racking is supported by motor-driven bases that move literally on floor rails. Instead of fixed aisles, the racks open one movable aisle at a time, allowing access when needed.

Benefits of Warehouse Racking for Safe and Smooth Work

Many warehouse racks offer benefits to workers, businesses, and their overall performance.

More Space And Better Organisation:

Strong racks help warehouses utilize vertical space effectively. That means the products are stacked high in the air on tall shelves. Everything is neat, visible, and easily separated.

Safe Handling And Reduced Workplace Risks:

Workplaces will be safer, as employees won’t strain to lift items that aren’t in the usual position. Also, forklifts operating in clear, wide aisles help reduce accident rates.

Faster Picking And Smoother Workflow:

Racking helps employees find the items they need quickly. Everything is in a clear place with labels that are easy to read, along with rows and sections that guide them when picking.

Long-Term Growth And Easy Expansion:

As a business expands, the warehouse racking system allows for easy addition of new shelves or aisles. It also helps to manage additional inventory in a stress-free manner.

How To Choose the Right Warehouse Racking System

Here are the steps to choose a well-designed warehouse racking system:

1. Identify The Type Of Products You Store

- Assess the size, shape, and weight of your products.

- These characteristics determine the storage method, rack types, and shelf dimensions required.

2. Review Your Warehouse Equipment

- Consider the tools and machinery employees use (e.g., forklifts, pallet jacks).

- Ensure the racking system aligns with how goods will be handled and moved during daily operations.

3. Analyze Space And Movement Patterns

- Measure aisle widths, shelf spacing, and workflow paths.

- Select racks that minimize wasted space and prevent awkward or unsafe movement around the warehouse.

4. Assess Future Storage Growth

- Plan not only for current inventory but for future changes in product type, size, or volume.

- Choose a flexible racking system that allows extensions, higher shelves, or aisle reconfiguration, reducing future upgrade costs.

5. Understand Load Capacity And Safety Ratings

- Check the load ratings listed on every rack component.

- Ensure the system can safely support the required weight without compromising its structural integrity.

- Select racks with verified safety certifications to maintain long-term stability and a safe working environment.

6. Consider Accessibility And Picking Speed

- For frequently picked items, ensure racks allow direct, fast access.

- Use systems like drive-in or double-deep racks for slower-moving bulk items.

- Match the racking design to your picking patterns to improve operational efficiency.

7. Evaluate Budget And Maintenance Costs

- Compare not just installation prices but also long-term maintenance, repair, and inspection costs.

- Investing in durable, high-quality racks reduces long-term upkeep and safety risks.

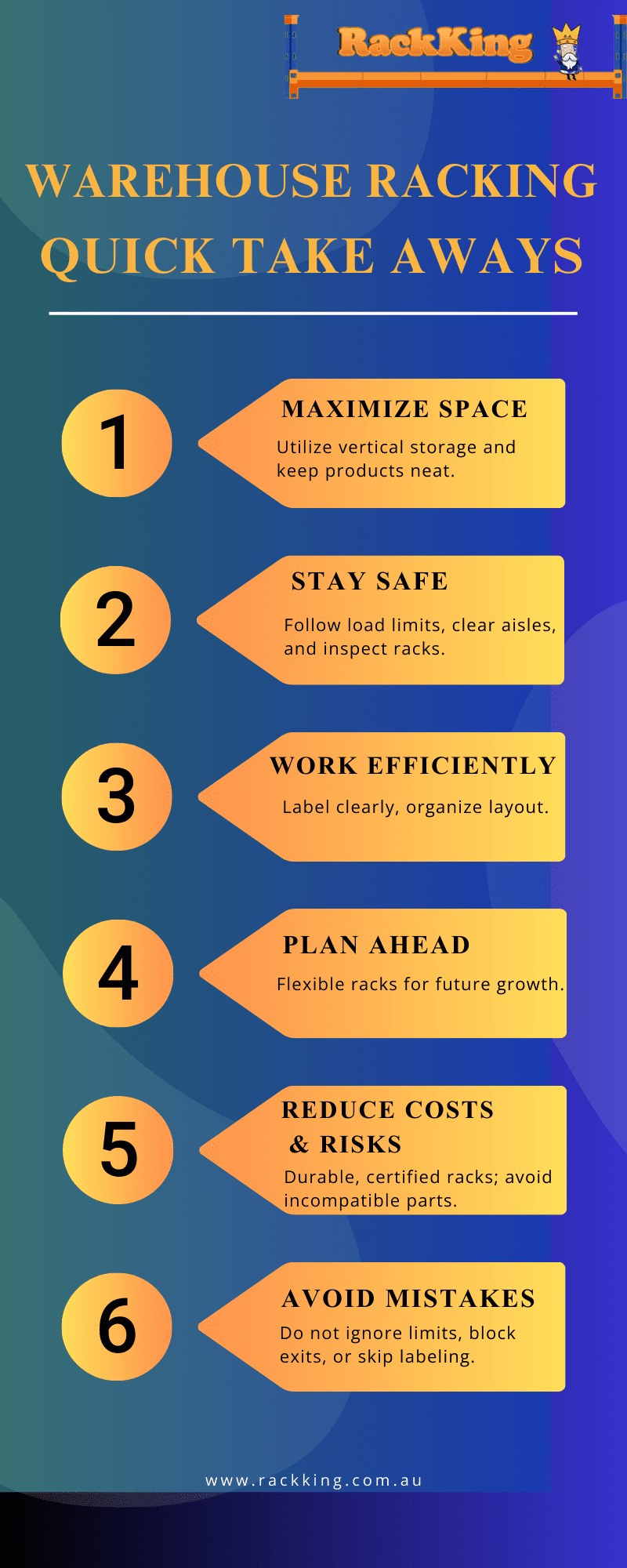

Warehouse Racking: Quick Takeaways

Mistakes to Avoid When Setting Up Warehouse Racking Systems

When building or arranging a warehouse racking system, several mistakes can lead to unsafe work, damaged goods, and slow operations; therefore, it is important to avoid them from the beginning to keep the warehouse safe and organized.

| Mistake | Explanation |

| Ignoring Load Limits | A common mistake is placing heavy items on shelves without checking how much weight the rack can safely hold, which increases the risk of bending, breaking, or sudden collapse. |

| Poor Aisle Spacing | Some warehouses have aisles that are too narrow, which makes it difficult for forklifts and workers to move safely, and this issue often leads to collisions, delays, and workplace injuries. |

| Incorrect Rack Assembly | Many problems occur when racks are assembled without following the correct instructions, including loose bolts, unstable frames, or shelves that do not sit evenly; therefore, checking everything during installation is extremely important. |

| Skipping Safety Inspections | Another mistake is forgetting regular inspections, because racks slowly weaken over time due to bumps, vibrations, and heavy daily use. Without inspections, small damages can grow into bigger safety risks. |

| Mixing Incompatible Rack Parts | Some warehouses use beams and frames from different brands or systems, and this mismatch often reduces strength and creates unstable connections. Using matching components helps maintain strong support. |

| Blocking Emergency Exits And Pathways | A serious mistake is placing racks or pallets where they block exits, fire equipment, or walkways, which slows down evacuation and creates hazardous conditions during emergencies. |

| Not Planning For Future Growth | Many businesses focus only on current storage needs and forget to plan for future products or changes, and this leads to expensive rework later, so choosing flexible racks helps support smooth expansion. |

| Poor Labeling And Inventory Marking | If shelves do not have clear labels or section markers, workers spend extra time searching for items, which increases delays, confusion, and picking mistakes. |

Conclusion

Creating a comfortable and safe warehouse environment requires both workers and managers to understand the advantages of each racking system and how these options support daily operations. By becoming familiar with the strengths, limitations, and ideal uses of different rack types, teams can make informed decisions that enhance productivity, reduce risks, and support long-term growth.

This knowledge helps ensure that storage systems align with product requirements, equipment capabilities, and movement patterns within the facility. When everyone involved recognizes how the right racking solution contributes to efficiency and safety, the warehouse becomes more organized, adaptable, and cost-effective. Ultimately, informed choices lead to better performance, fewer disruptions, and a more secure workplace for all.

Need Help Staying Compliant?

Choosing the right racking system is key to a safer, smarter, and more efficient warehouse. If you want reliable storage that meets Australian standards and supports long-term growth, RackKing Australia is here to help.

Get expert advice and fast quotes today. Enhance your warehouse with safe, durable, and space-saving racking solutions.

Related Articles:

Warehouse Racking Australia: Holiday-Ready Safety Guide

Common Rack Mistakes to Avoid for Warehouse Racking Safety

FAQs

What Type Of Product Is Appropriate For A Heavy-Duty Load?

Pallet racks, which are selective or drive-in, can handle large loads. Beams, frames, and frames must be sturdy to avoid the system bending.

Why Do Warehouses Use Cantilever Storage?

You store wood pipes, metal bars, and other long, awkward pieces in this storage unit.

How Do Mezzanine Racking Systems Help Storage?

Mezzanine Racking Systems feature raised floors for extra storage space or to create work stations.

How To Select The Right Shelving?

Storage layouts are influenced by factors like forklifts or product dimensions and weight, but also daily tasks, workplace, and storage.