As the holiday season approaches, warehouses across Australia become increasingly busy with rising orders and long hours of stocking, picking, packing, and moving. This busy period brings strong pressure each week, making it important for every warehouse racking system to remain steady and organized so workers move safely without confusion or dangerous mistakes. To achieve this, businesses must follow early planning steps, complete safety checks, conduct thorough storage inspections, and follow clear warehouse safety standards to keep racks, pallets, and workers protected as the pressure increases.

Why the Holiday Rush Puts Extra Strain on Warehouse Racking

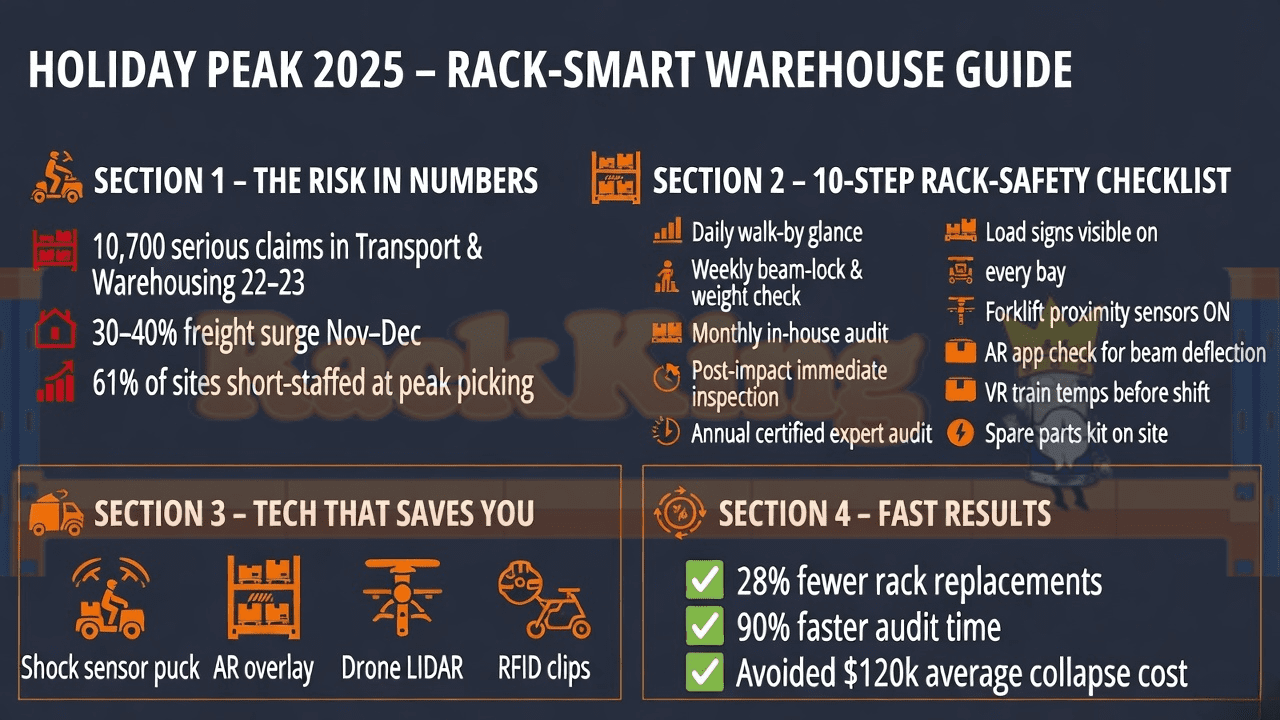

A few numbers show just how real that pressure is. SafeWork Australia’s latest tally reveals the transport, postal & warehousing sector logged 10,700 serious comp claims in 2022-23—over one-eighth of the national total, so the injury risk jumps sharply when seasonal overtime kicks in. Add the Australian Logistics Council’s finding that pre-Christmas freight volumes routinely swell by 30-40 %, pushing many DCs to juggle 1.4× their normal daily pallet moves, and it’s easy to see why racks take extra strain. On top of that, Dematic’s 2023 survey notes 61 % of warehouse managers head into the peak with “significant” or “severe” labour shortages, meaning more temporary staff who may not yet know your specific safety protocols.

The holiday season brings a significant increase in product movement. This quick rise can grow faster than expected. Fast movement puts pressure on every shelf, every pallet rack, every forklift path, and every picking area inside the warehouse. This sudden change sometimes creates rushed decisions, unsafe stacking habits, and overloaded beams that make the warehouse unsafe. This makes it very important to understand how your racks must stay ready before the holiday season begins.

Increased Stock Levels

During the holiday season, goods arrive in huge amounts and stay inside the warehouse for longer than usual, which means:

- Heavier pallet loads

- Taller stacking levels

- More beams holding weight at once

- More forklifts travel inside narrow aisles

All of these create extra pressure on the racking system and the workers who move around it.

Faster Picking And Packing

When holiday orders rise sharply, workers must move quickly to meet demand, and this fast movement sometimes leads to tilted pallets, poor stacking, and unsafe loading. A strong layout and strict pallet racking safety rules help reduce these problems.

Importance Of A Strong Warehouse Racking System in Australia

A strong racking system helps the whole building operate in a safe and stable way.

Racking as the Backbone of Storage Solutions

The racking system helps the warehouse stay organised by creating the structure for:

- Proper pallet placement

- Stock rotation

- Product arrangement

- Forklift direction and travel paths

A strong racking structure helps workers feel more confident during busy days.

Why Australian Warehouse Safety Standards Matter

Warehouse safety standards in Australia help guide businesses so their racks remain strong, safe, and compliant. These rules explain:

- Load limits for beams

- Upright safety protection

- Pallet size rules

- Installation steps

- Inspection routines

These standards protect the warehouse from dangerous situations or racking collapse.

Why You Must Inspect Warehouse Racking Before the Holiday Rush

Before the holiday season begins, the warehouse must complete a full warehouse racking inspection. This inspection helps identify problems early, ensuring busy holiday days stay safe for everyone working inside the building.

What To Check During an Inspection?

During a full inspection, workers or professional inspectors look for:

- Cracked beams

- Bent or twisted uprights

- Missing safety clips

- Damaged frames

- Rust spreading across metal

- Loose base plates

- Uneven pallet stacking

- Blocked aisles

Even a minor issue can compromise the whole racking structure.

How Often Should A Warehouse Racking Inspection Happen?

Racking Inspection happens due to:

Daily “walk-by” glance: At every shift change, lift drivers look for obvious dents, bent braces, loose anchors, or leaning frames; if it seems wrong, tag it and report it.

Weekly floor-level check: Supervisors inspect pallet weights, beam locks, missing safety pins, and upright footplates; takes 10 min per aisle, preventing 90 % of slow-motion collapses.

Monthly in-house audit: A trained “rack safety officer” photographs every impact point, measures deflection (AS 4084 allows max 1/200 of beam length), and logs it in the WMS; damaged bays are offloaded within 24 h.

Annual expert inspection: A certified inspector (usually SEMA or FEM trained) arrives with lasers, gauges, and ultrasound; you receive a colour-coded risk map and a compliance certificate for your insurance file.

Post-impact or re-configuration: Hit by a forklift? Re-slotted beams for new SKUs? Inspect immediately; 40 % of rack failures occur within 48 h of an unreported bump (SafeWork NSW 2022 data).

After seismic events or floods: Even a 3.0 magnitude tremor can loosen base plates; check plumb and anchors before restocking.

Pro tip: Turn the schedule into a QR-coded checklist on each rack end; when the code is scanned, the due date automatically updates, and the safety manager gets an alert if anything is overdue.

Why Professional Inspectors Help?

Professional inspectors understand how the racking structure works and know how to:

- Identify hidden damage

- Measure safe load levels

- Suggest correct repairs

- Recommend safety tools

- Help design safer layout plans

Their support helps prevent expensive damage or worker injuries.

Preparing Your Pallet Racking System For Heavy Holiday Loads

The pallet racking system must stay strong during the holiday season because heavier loads add intense pressure to upright frames, beams, and shelves.

Check Load Capacity Labels

Each pallet bay must display a clear and correct load label with safe weight limits. Workers must follow the label numbers to keep the racks stable.

Improve Pallet Quality

Old pallets with broken boards make the warehouse unsafe because weak pallets slip, tilt, or collapse under heavy loads. Strong and even pallets help protect workers and goods.

Strengthen Rack Protection

Useful rack protection tools include:

- End-of-aisle protectors

- Upright guards

- Guide rails

- Back stops

These tools help protect racks from forklift damage.

Improve Beam Safety

Beams must have strong safety pins that lock them into place, because missing safety pins make beams unstable even when they look straight.

Tech That Keeps Warehouse Racking Safe (Australia, 2025)

# | Tool / Tech | What It Does | Price (AUD) | Key Benefit | Limitation |

1 | Rack-Impact Sentry | Alerts when a rack gets hit (>8G) | $95 + gateway | Stops hidden damage early | Needs a strong LoRa signal |

2 | AR-Rack Inspector App | AR checks beam deflection | $39/mo | Fast, accurate visual checks | Needs newer phones |

3 | LiDAR Rack-Copter | Drone scans plumb/lean | $350 per aisle | No scissor lift needed | CASA pilot rules |

| 4 | UWB Proximity Badge | Slow forklifts near racks | $1.2k/forklift | Big drop in impact events | Line-of-sight limits |

| 5 | RFID Beam-Lock Clip | Confirms beams are properly seated | $3 each | Prevents dropped beams | Metal interference |

6 | WMS Rack-Health Module | Tracks rack issues + work orders | $2k/mo | Clean audit trail | Staff must scan |

7 | Digital Twin Model | Live 3-D rack model | $25k setup | Test changes risk-free | Needs as-built drawings |

| 8 | Load-Cell Smart Beam | Shows real-time beam load | $550/beam | Stops overload failures | Cables can get damaged |

| 9 | Tower-Cam CCTV Mast | Tall cam records pallet moves | $4.5k | Identifies who hit racks | Needs solid 4G |

10 | VR Rack-Safety Trainer | Teaches impact safety in VR | $195 + $2k licence | Fewer new staff hits | 5% get motion sick |

Organizing Storage Solutions For Holiday Inventory Overflow

Holiday months bring a strong rise in stock volume, and smart warehouse storage solutions help warehouses use space in a safe and organized way.

Use Vertical Storage Safely

Tall storage helps save floor space, but workers must follow:

- Sprinkler clearance rules

- Safe forklift reach height

- Beam load limits

- Pallet weight rules

Tall storage must stay safe and stable.

Create Mixed Storage Zones

Warehouses may use a mix of:

- Selective racking

- Drive-in racking

- Push-back racking

- Shelving Bays

This helps store different goods with different movement speeds.

Label Every Area Clearly

Clear labels help workers locate goods more easily and reduce mistakes during busy periods.

Training Workers For Holiday Season Pressure

Workers must understand how to use the racking system safely and correctly, as trained workers help prevent dangerous mistakes.

Teach Safe Pallet Loading

Workers must place pallets:

- Straight

- Centered

- Even

- Without a dangerous overhang

Overhanging pallets strike uprights and damage them.

Teach Safe Forklift Operation

Forklifts bring many risks if workers move too quickly. Workers must drive slowly, keep forks low when travelling, and observe corners.

Teach Emergency Procedures

Workers must know:

- How to report racking damage?

- How to block unsafe areas?

- How to move safely during emergencies?

Safe knowledge protects everyone.

Creating A Holiday-Ready Warehouse Layout

A strong and organised layout helps the warehouse remain calm during the busy holiday season.

Keep Fast-Moving Stock Near Shipping Zones

This reduces worker travel time and helps the warehouse stay free from large crowds in narrow aisles.

Keep Aisles Wide and Clean

Aisles must not have:

- Loose wrapping

- Empty pallets

- Fallen boxes

- Broken pieces of equipment

A clean aisle helps avoid unsafe accidents.

Add Temporary Overflow Areas

Holiday months sometimes require extra space for bulk goods or fast-moving items.

HOLIDAY PEAK 2025–RACK-SMART WAREHOUSE GUIDE

Final Holiday Racking Preparation Checklist

Here is a simple checklist that helps your warehouse stay ready:

- Inspect each of the rack uprights and frames

- Repair damaged parts

- Add guards and aisle protection

- Confirm load limits

- Replace old pallets

- Retrain workers

- Keep aisles clean

- Place fast-moving items near shipping

- Label every rack clearly

- Create overflow zones

- Update safety steps

- Improve tracking tools

Conclusion

The holiday season brings intense pressure to every warehouse, meaning that every pallet, every forklift, and every worker must follow strong safety steps. Hence, the building remains organised and stable, and by following storage solutions, detailed warehouse racking inspection routines, and warehouse safety standards in Australia, the business builds a strong foundation for smooth operations. Preparing early helps the warehouse operate smoothly and productively during the busiest days of the year.

Need Help with Warehouse Racking?

For safe and efficient warehouse storage, professional pallet racking installation, or regular safety inspections, our experts provide fully certified solutions for every warehouse type. Get fast quotes, practical guidance, and compliant racking designed to keep your workers safe and your warehouse organised. Visit RackKing today for a complimentary assessment and expert advice on your warehouse storage requirements.

FAQs

Why is a warehouse racking inspection important before the holiday season?

A warehouse racking inspection helps find early damage, such as bent beams or missing pins, before the busy season begins, which helps protect workers from accidents and goods from breaking.

How do storage solutions help during holiday overflow?

Storage solutions help the warehouse use space wisely, organise goods by movement speed, and keep the building safe and easy to move through during holiday pressure.

What steps help workers stay safe during the holiday rush?

Workers stay safe when they follow slow forklift movement, correct pallet placement, emergency steps, and safe lifting instructions taught during training.

How do warehouse safety standards in Australia support businesses?

Warehouse safety standards in Australia give rules for load limits, rack strength, inspection routines, and safe layout plans so businesses follow the right steps for a secure workplace.