Warehouses today face growing pressure to move goods faster, operate more safely, and control costs in an increasingly competitive supply chain environment. In Australia, these demands are shaped further by strict work health and safety requirements and rising customer expectations. Choosing the right warehouse operational tools plays a direct role in how efficiently a facility performs, how well risks are managed, and how prepared the operation is for future growth. This article explains the core equipment categories that support handling, packing, storage, and loading operations.

This article is based on independent research from Australian government regulators, industry associations, professional standards organisations, and logistics publications.

What Are Warehouse Operational Tools?

Warehouse operational tools include the equipment, machinery, and safety systems used to move, store, pack, and load goods within a warehouse or distribution centre. According to Safe Work Australia’s guidance on managing risks from plant and machinery in the workplace, efficient warehousing depends on the integration of material handling, safety, and packing systems rather than isolated equipment purchases.

Industry professionals typically group these tools into five functional categories:

- Material handling equipment

- Warehouse safety equipment

- Warehouse packing equipment

- Industrial warehouse equipment

- Warehouse loading equipment

Each category plays a distinct role in improving throughput, reducing injuries, and maintaining compliance with Australian work health and safety laws.

1. Material Handling Equipment

Material handling equipment (MHE) refers to gear used for moving, lifting, storing and positioning goods throughout a warehouse. According to Australian material handling guides, choosing the right mix of equipment reduces labour costs, boosts productivity and helps manage heavier loads safely.

Forklifts

Forklifts are essential in warehouses for lifting and transporting heavy palletised loads. They come in electric, diesel and gas models. Variants include reach trucks (for narrow aisle work) and order pickers (for high-shelving order fulfilment). Proper training and safety checks are required because improper use can cause serious accidents, as outlined in the Forklifts information sheet.

Pallet Jacks and Walkie Stackers

Pallet jacks (manual or powered) let operators move palletised loads short distances. Walkie stackers are similar but motorised and capable of lifting pallets higher within storage racks.

Conveyor Systems

Conveyors automate the horizontal transfer of items, especially in high-volume operations. They reduce manual handling and help standardise workflow from receiving to packing stations.

Automated Guided Vehicles and AMRs

Automated guided vehicles (AGVs) and autonomous mobile robots (AMRs) use sensors or programmed paths to transport goods with minimal human input. These systems are increasingly common in large Australian distribution facilities looking to reduce labour and error.

Lift Tables and Positioning Equipment

Lift tables help reposition goods to an ergonomic working height, reducing risk of injury and process delays. These are especially helpful in packing and preparation zones.

Storage Foundations (Pallet Racking)

Pallet racking systems maximise vertical space and organise palletised inventory. Different racking types suit different operational needs, from selective racking for high-turnover items to drive-in systems for bulk storage. Proper inspection and adherence to load limits is essential to prevent rack collapse and associated injuries.

2. Warehouse Safety Equipment

Safety is non-negotiable in environments with moving machinery and heavy loads. Warehouses should incorporate protective gear, visual controls and operational safety tools to lower incident risk.

Essential Safety Tools

- Personal Protective Equipment (PPE): Hard hats, high-visibility vests, steel-toe boots, safety glasses and gloves protect workers from common hazards and are often mandated by Australian workplace safety regulations under the Work Health and Safety Act 2011.

- Barrier Rails and Signage: Physical barriers and clear directional signage help separate personnel from equipment pathways (like forklift routes), minimising collisions.

- Anti-Slip Mats and Flooring: Safe walkways and anti-slip surfaces decrease slipping risks, especially in high-traffic zones.

- Dock Safety Tools: Wheel chocks, dock locks and status lights improve safety during loading/unloading by preventing equipment movement when personnel are operating on docks.

These safety measures should be combined with regular training and documented safe operating procedures as outlined by Safe Work Australia.

3. Warehouse Packing Equipment

Packing equipment supports the preparation of goods for storage and dispatch. The right tools improve packaging consistency and reduce damage in transit.

Common Packing Tools

- Strapping and Banding Machines: Strapping machines secure pallet loads or boxes with tensioned bands, improving load stability and shipping safety. They come in semi-automatic and fully automatic configurations.

- Stretch Wrap Machines: These automate wrapping pallets tightly in plastic film, protecting goods from shifting and external contamination.

- Industrial Scales: Accurate scales are critical for freight cost calculations, load verification and compliance with carrier rules.

- Packing Tables and Workstations: Ergonomically designed stations streamline packing and reduce worker strain.

Packing tools are often evaluated together with productivity studies to balance speed, cost and damage reduction.

4. Industrial Warehouse Equipment

This category captures tools that help support broader storage and workflow activities.

Core Industrial Tools

- Pallets and Containers: Standardised pallets (including Australian standard pallets) serve as the basic unit for stacking and moving goods.

- Bins, Totes and Cart Systems: These keep smaller items organised and reduce picking errors.

- Access Platforms and Ladders: Safe access equipment ensures personnel can reach high shelves without unsafe climbing practices.

- Weighing and Measuring Tools: Accurate dimensioning and weighing tools improve space planning and load management.

These support functions ensure that warehouses operate with minimal disruption and maximal storage clarity. For operations dealing with particularly heavy inventory, specialized industrial storage systems provide the structural capacity needed to safely handle high-weight pallets and equipment.

5. Warehouse Loading Equipment

Loading and unloading are turning points in any operation. Dedicated loading tools bridge warehouses and transport vehicles safely and efficiently.

Key Loading Tools

- Dock Levelers and Ramps: These bridge height differences between truck beds and warehouse floors, allowing forklifts or pallet jacks to move goods without damaging equipment or products.

- Portable Dock Plates: Smaller and mobile compared with full levelers; these are useful for flexible loading zones.

- Edge-of-Dock Devices: Compact devices that provide quick adjustments for trucks with minor height variations.

Loading equipment reduces manual staging and accelerates transition into transport, which lowers turnaround times.

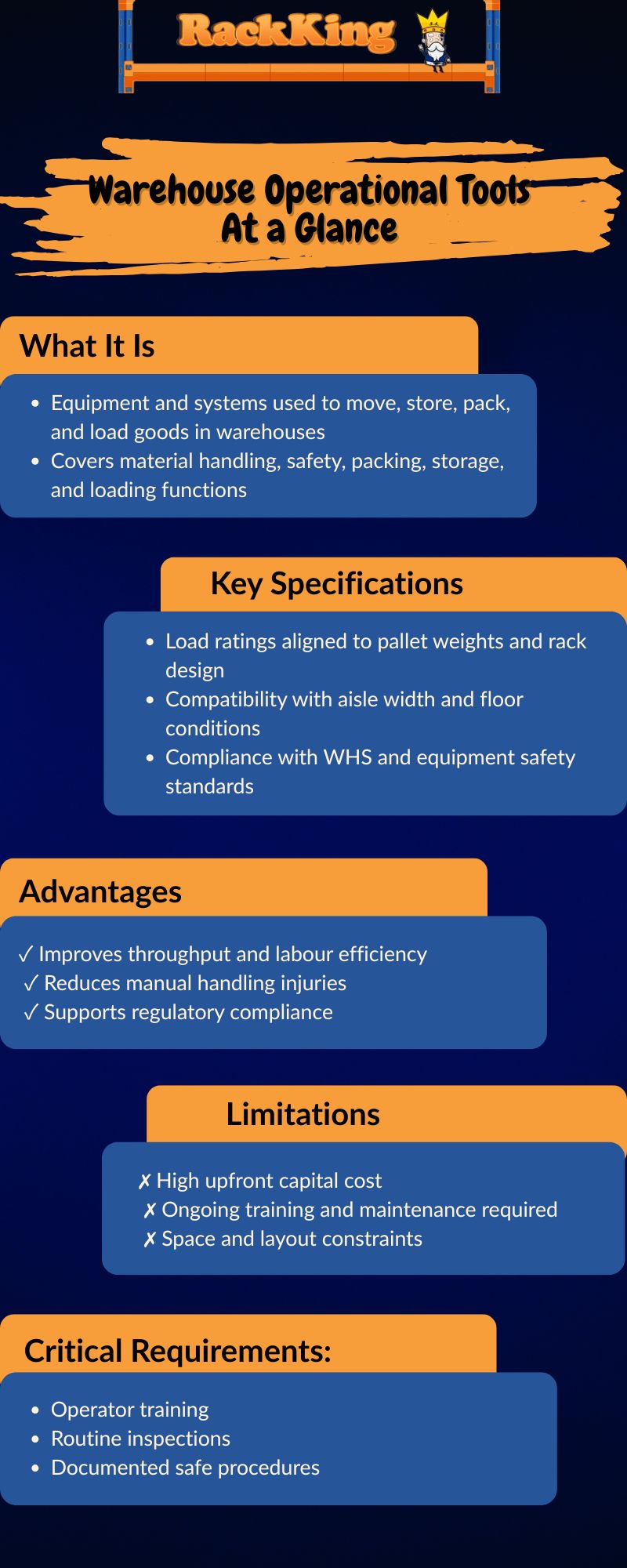

Warehouse Operational Tools At a Glance

Practical Guidance for Purchasing

Before buying warehouse operational tools, industry standards and expert guidance highlight several considerations:

- Assess Your Workflow: Identify tasks that take the most time or have the highest injury risk. Tools that address these directly yield the greatest ROI.

- Compliance and Standards: According to SafeWork NSW forklift guidelines, ensure equipment meets applicable Australian standards and safety regulations.

- Training and Support: Choose suppliers that offer operator training and ongoing support.

- Maintenance Plans: High-use equipment needs structured preventative maintenance to avoid costly downtime.

- Scalability: Select tools that can adapt or scale with your business growth.

The Model Code of Practice: Hazardous manual tasks provides detailed guidance on selecting appropriate mechanical aids and equipment.

Conclusion

Selecting warehouse operational tools should be a considered business decision, not a reactive purchase. Research consistently shows that productivity gains, safety improvements, and long-term cost control come from matching equipment to workflow, volume, and compliance requirements. Material handling, safety, packing, industrial storage, and loading equipment all work together to support reliable warehouse operations. For Australian buyers, understanding standards, inspection obligations, and lifecycle costs is just as important as comparing prices. When in doubt, industry guidelines and qualified professionals provide the clarity needed to invest with confidence and build a safer, more efficient warehouse.

Need Help Selecting the Right Warehouse Equipment?

Choosing compliant, efficient warehouse operational tools is critical for safety and productivity. RackKing Australia provides expert guidance on material handling, storage, and safety equipment that meets Australian standards.

Get expert advice and fast quotes today. Upgrade your warehouse with reliable, standards-compliant operational tools.

Related Articles:

Common Rack Mistakes to Avoid for Warehouse Racking Safety

Warehouse Racking Australia: Holiday-Ready Safety Guide

FAQs

How do I choose the right forklift for my warehouse?

According to WorkSafe Victoria’s forklift safety guide, consider load weight, aisle width and facility height. Counterbalance forklifts suit general use, while reach trucks work well in narrow aisles. Supplier consultations are recommended to match specifications to operations.

Are automated guided vehicles worth the cost?

For facilities with predictable, high-volume movement, AGVs can reduce labour and error. Their value depends on throughput, space layout and workforce strategy.

What safety gear is legally required for warehouses?

Requirements vary by jurisdiction, but at a minimum, PPE (helmets, eye/ear protection, high-visibility clothing) and clear signage are standard. Facilities should also follow local workplace safety legislation as established by the Work Health and Safety Regulations 2011.