A multi-level mezzanine is a modern way to solve the problem of limited space when a business needs more room to grow but does not wish to move to a new place. Instead of buying more land or building new walls, the idea is to build upward and make use of the empty air above the floor.

Many Australian companies in warehousing, logistics, and manufacturing have started using mezzanine storage solutions because they help them expand quickly without stopping their daily work or spending too much money. These multi-level mezzanine floors, designed and installed by professional mezzanine floor builders in Australia, have become an intelligent choice for people who wish to make their buildings more useful and productive.

In the following article, we will look deeply at how mezzanine design, installation, and use bring more space, better workflow, and long-term value to every business that chooses to build smarter instead of bigger.

What Is a Multi-Level Mezzanine?

A multi-level mezzanine floor is a strong steel structure that stands freely inside an existing building and adds new floors above the ground without changing the main building shape. It is made to create extra working areas, storage sections, or office spaces within the same footprint, turning unused height into useful square meters. These mezzanines are built in different styles, such as single-tier for small operations, double-tier for medium projects, and triple-tier for large warehouses that require many levels of activity.

Modern mezzanine floor builders engineer systems that comply with Australian safety and load-bearing standards, making every installation a long-lasting and trusted investment.

Smart Way to Expand Without Construction

Many businesses today face the same big problem, which is the rising cost of property and the lack of enough working space. When the cost of buying or renting new land keeps going higher every year, companies start to look upward instead of outward. A multi-level mezzanine floor gives them a smart and safe way to build new working levels inside the same building. This helps them save money, time, and energy while making the best use of the area they already own.

According to a recent project example, installing a two-tier mezzanine floor increased usable space by up to eighty percent without changing the building footprint or stopping the daily workflow. This shows how a smart vertical expansion brings more value without the trouble of moving or building again.

Key Components of a Mezzanine System

Every strong and reliable mezzanine structure is made of several important parts that work together to form a safe and lasting system. These parts are designed carefully to meet Australian standards and to support the daily activities of warehouses and industries that use them.

Main Elements Include:

These main key components of a mezzanine system.

Steel Framework:

The whole strength of a mezzanine starts with its steel frame. High-quality steel is used to make columns, beams, and joints that hold the upper floors firmly. This frame is built with great care for durability, balance, and safety so that it stays stable even under heavy loads.

Decking and Flooring Options:

The walking surface or deck of a mezzanine may be made from timber panels, steel grids, or composite materials. The type of decking is chosen based on how the space will be used. For example, heavy machines may need steel decking while storage areas may use timber or composite floors for a lighter finish.

Access Systems:

Safe movement between levels is made possible by stairs, handrails, safety gates, and even goods lifts. These access systems help workers reach every area of the mezzanine easily while keeping them safe at all times.

Safety and Compliance:

All designs follow Australian Standards AS 4100 for steel structures and AS 1657 for platforms, stairs, and walkways. This means that every part of the mezzanine is checked for proper weight limits, height clearance, and safety barriers before it is used.

Professional engineers who provide mezzanine design Australia also make sure that each system fits perfectly with existing equipment, such as racking, shelving, and conveyor lines. This enables a seamless flow of materials between floors and enhances the overall workflow.

For better understanding, a schematic or CAD layout image is often used during planning to show exactly how each part of the mezzanine will fit inside the building.

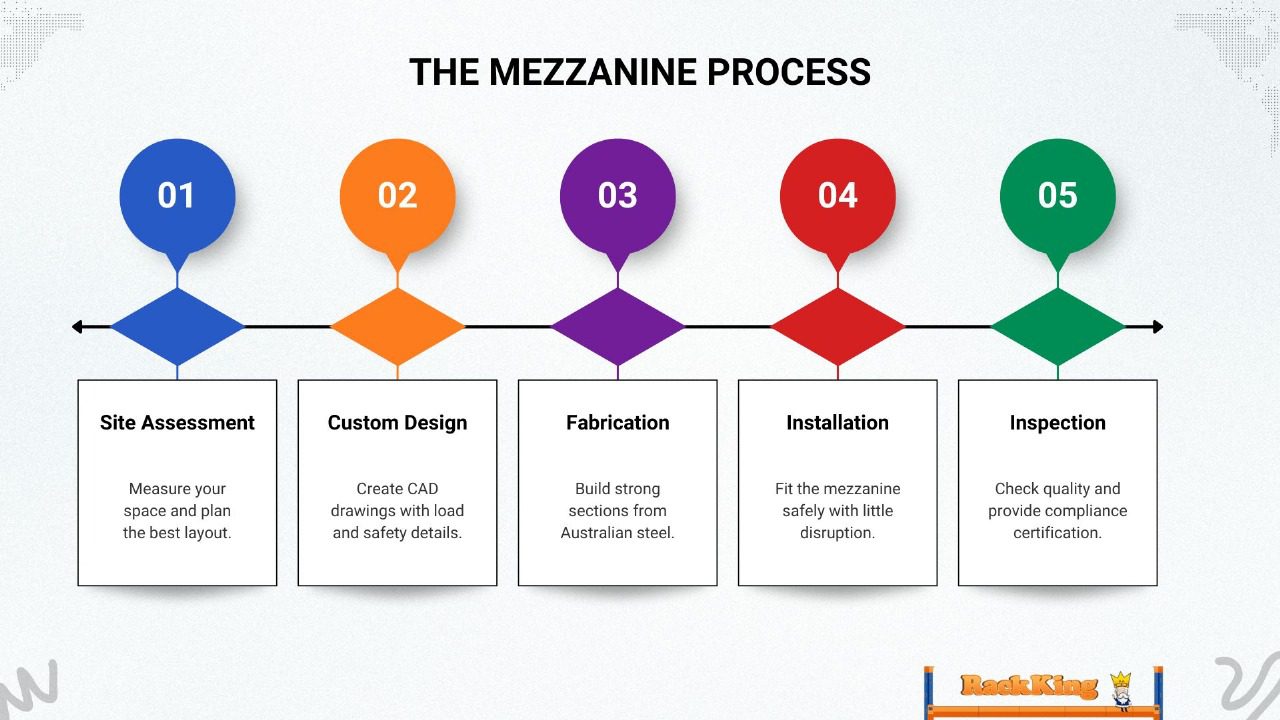

From Design to Installation—The Mezzanine Process

At Rackking, we have refined mezzanine installation into a smooth and fast process that fits perfectly around your operations. Our team of expert mezzanine floor builders follows a clear and well-planned path to deliver every project with care, precision, and quality. Each stage of our mezzanine design Australia process is focused on safety, accuracy, and creating extra space that works for your business needs.

Step 1: Site Assessment

The process begins with a complete visit to your location, where we carefully measure the height, layout, and existing structure of your space. This step helps our mezzanine floor builders understand the true potential of your building and identify the best placement for the mezzanine system.

Step 2: Custom Design and CAD Layouts

After the site inspection, our design team starts developing detailed computer drawings and engineering layouts. Each plan includes important calculations about load ratings and strength. Every mezzanine design Australia project is made to suit your specific requirements, whether it is for storage, office use, or production space.

Step 3: Fabrication

Once the design is approved, the fabrication process begins. We use strong Australian steel that is known for its high quality and durability. The structure is made in sections to ensure precision and easy assembly on-site.

Step 4: Mezzanine Installation

The mezzanine installation is carried out with great attention to safety and timing. Our team works carefully to ensure minimal disruption to your daily activities while the system is being fitted. Every bolt and beam is checked to guarantee long-lasting strength and stability.

Step 5: Inspection and Compliance Certification

When the work is complete, each mezzanine floor is inspected and certified according to Australian safety standards. All the necessary documents are provided to confirm that the mezzanine installation meets engineering and compliance requirements.

Turning Empty Airspace Into Profit

A multi-level mezzanine floor is one of the most effective ways to create additional space without altering the building itself. Instead of expanding outward, it allows businesses to grow upward, using the airspace that is already there. Below are the key advantages that make this solution so valuable across industries in Australia.

- Maximised Space Efficiency

The system transforms unused vertical areas into productive zones, helping warehouses, factories, and offices make full use of every metre of their property.

- Modular and Scalable

Each level is designed to be flexible and easily expandable. As your company grows, more levels or access points can be added without any major changes to the original structure.

- Cost-Effective Growth

A multi level mezzanine floor provides more room at a lower cost compared to building extensions or moving to a new site. It saves both time and financial resources while delivering long-term value.

- Fast Installation

The installation process is quick and efficient. It allows businesses to keep working with little interruption while the new floor is being completed.

- Customised Layouts

Every mezzanine storage solution is built to match the type of work done in that space. Whether it is a warehouse, an office, or a production area, the layout is tailored for comfort, safety, and performance.

Australian companies rely on mezzanine solutions Australia-wide for fast, scalable, and reliable expansion that supports growth without extra land or construction costs.

Who Benefits from Multi-Level Mezzanines?

A multi-level mezzanine is useful across many industries, offering space solutions that suit different kinds of operations. These flexible structures help improve workflow, organisation, and productivity for a wide range of businesses throughout Australia.

- Warehousing and Logistics

Many warehouses use warehouse mezzanine systems to create tiered storage areas and picking stations that increase efficiency and make handling goods easier.

- Manufacturing

Factories and workshops use mezzanines for production lines, equipment platforms, and maintenance areas that keep heavy machinery organised and accessible.

- Retail

Retail stores use mezzanine design Australia solutions to add stockrooms and display sections that allow them to manage more products in limited floor space.

- Automotive

Car service centres use mezzanines to store spare parts, tools, and accessories, helping technicians work faster and more efficiently.

- Aviation

The aviation sector uses these elevated structures for maintenance, inspection, and storage, giving engineers safe and structured access to aircraft components.

From Perth warehouses to Melbourne manufacturing hubs, mezzanine solutions Australia-wide are reshaping industrial efficiency and providing new ways to use space wisely and safely.

Safety, Compliance, and Engineering Standards

Safety is always the highest priority in every mezzanine installation completed by Rackking. Each structure is designed and inspected to meet strict Australian building codes, including AS 4100, AS/NZS 1170, and AS 1657. These standards cover everything from the strength of steel materials to the height and width of handrails and stairs.

All mezzanines come with certified load ratings that confirm how much weight they can safely support. Fire safety measures and proper access control are also part of the design to protect workers and equipment. Each mezzanine installation is backed by engineering certification and compliance documentation that proves every detail meets Australian safety and building regulations.

Why Choose Rackking and Mezzanine Floor Builders

Trusted Experience and Quality Work

Rackking Mezzanine Floor Builders have more than thirty years of strong experience in creating safe, modern, and reliable mezzanine systems across Australia. Their team works with great care from the first design idea to the final installation, making sure every project is handled with attention, precision, and quality.

Strong Design and Smooth Installation

Each mezzanine is made with detailed engineering and clear CAD layouts that match the shape and purpose of your space. The company uses high-quality Australian steel that gives lasting strength and safety. The installation process is well-planned and fast, allowing your work to continue without much disturbance.

Complete Service and Lasting Support

Rackking provides full support even after the installation is finished, along with safety and compliance documents. Their focus on strength, honesty, and reliability makes them a trusted name for mezzanine solutions Australia-wide.

Conclusion

A multi-level mezzanine floor is the smartest, safest, and most flexible way to expand usable space without changing your building. Rackking Mezzanine Floor Builders are trusted experts in mezzanine solutions Australia-wide, helping businesses reach new heights with systems that combine design, safety, and performance.

Also Read:

Mesh Load Decks Benefits, Installation & Usage in Warehouses

FAQs

What is a multi-level mezzanine floor?

A multi-level mezzanine floor is a strong steel structure that creates extra levels of space inside a building, allowing a business to use the empty air above the ground for storage, work areas, or offices.

How do mezzanine floor builders complete the mezzanine installation?

Mezzanine floor builders start with a site visit, prepare detailed mezzanine design Australia drawings, build the structure from high-quality Australian steel, and finish the mezzanine installation with safety and accuracy.

Are warehouse mezzanine systems safe to use in Australia?

All warehouse mezzanine systems are made to follow Australian standards, which include safety rules, load ratings, and fire protection, ensuring strong and reliable mezzanine storage solutions.