You may not have known that 25% of warehouse accidents occur because products fall off racks or from shelves. These incidents result in product damage and workplace hazards. Researchers have found that safety concerns are high among warehouse managers. A secure storage system involves not only placing pallets in beams, but also includes using the appropriate decking material to support the different loads. Mesh Load Decks are trusted in the industry and offer strength, airflow, fire code compliance, and flexibility.

If a warehouse uses mesh decking, it protects both its employees and the products. They also have a safe, durable solution to the industry’s strict safety regulations.

In this article, we will explain all of these ideas in detail, so you can understand why mesh decking is so important, how it helps warehouses stay safe, and why so many managers believe it is the best choice for protecting both people and products.

What Are Mesh Load Decks?

In Australia, warehouse managers are continuously searching for safe and reliable storage solutions that can accommodate various types of products while adhering to strict safety standards. One of the most trusted options for this purpose is mesh load decks.

Mesh load decks are strong panels that are made from steel wire, which is carefully welded together, and these panels are placed on pallet racking to create a safe and reliable storage surface.

Mesh decks that have high weight ratings are the best choice for warehouses that store heavy automotive parts, while lighter mesh decks are used in retail centres to hold cartons and other lighter products.

Key points to remember:

- Warehouse decks are made from durable, strong, and welded-together steel wires.

- Weights are supported by the channels, which distribute loads equally. They reduce strain and increase the lifespan of shelving.

- When air is allowed to flow freely, it keeps the boxes and cartons in a stable state and makes them easy to move.

- There is a wide range of sizes and ratings to accommodate different requirements.

- Lighter versions of heavy-duty models suit industries where flexibility is most important, such as retail or general stores, and are perfect for those who work in the automotive industry.

- These features make them an ideal choice for Australian businesses that need storage that is strong but also efficient.

Why Choose Pallet Racking Mesh Decks for a Warehouse?

Pallet racking mesh decks are becoming more common in warehouses because they make storage safer, stronger, and more reliable. Managers want systems that protect workers, follow fire safety rules, and hold many types of products. Mesh decks help achieve all of these needs.

Main benefits of pallet racking mesh decks:

- Safety first: Prevent products from falling off racks and causing harm.

- Fire safety: Open mesh allows air and water from sprinklers to move through.

- Strong support: Carry different sizes and weights of products with ease.

- Long-lasting: Built to handle daily use in busy warehouses.

- Flexible fit: Works with many storage systems and product types.

Using mesh decks gives a warehouse a safe, practical, and trusted storage solution

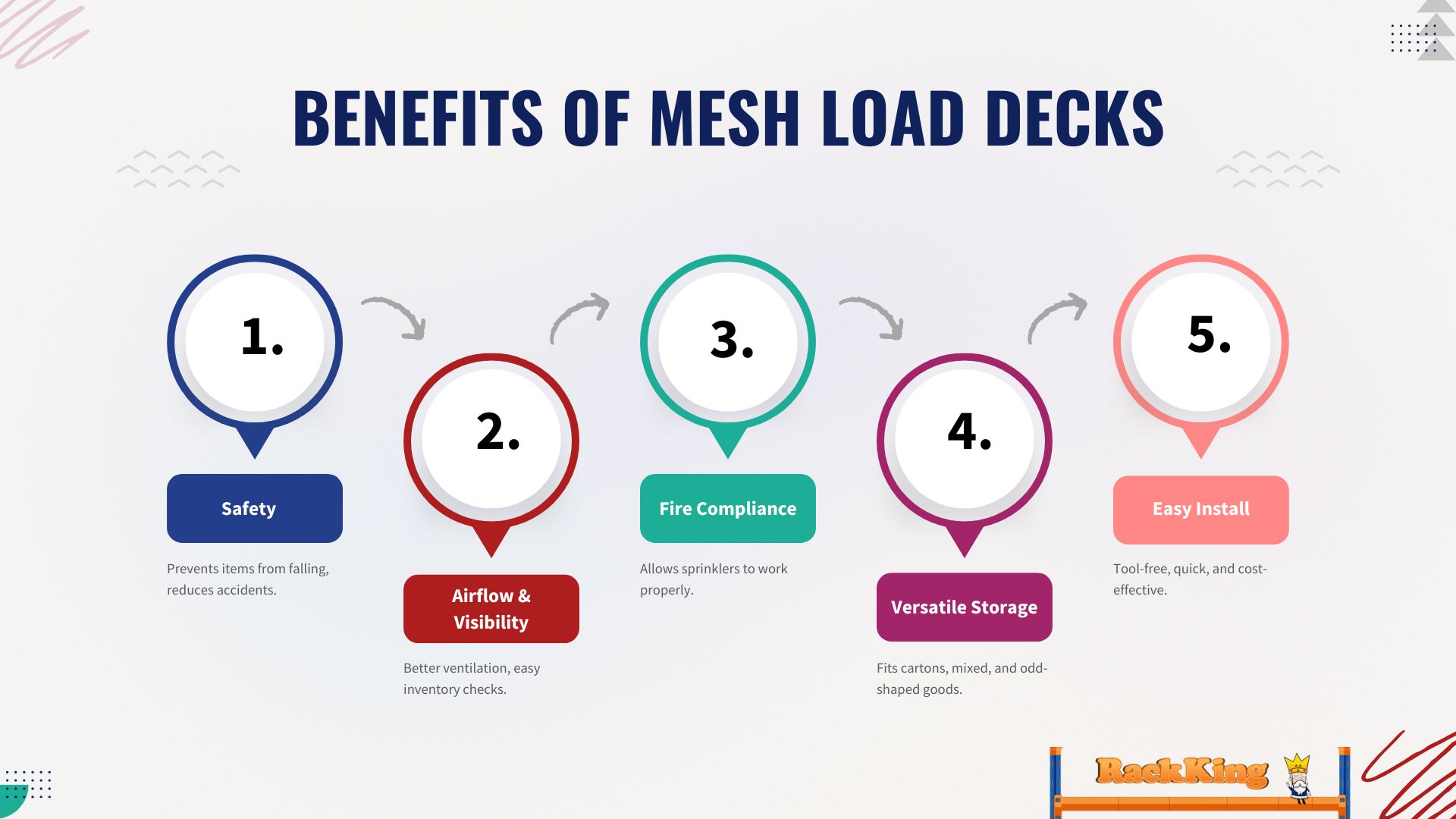

Benefits of Mesh Loads Decks

Improved Safety

Security is an important benefit. When the deck is missing, it’s common for items to fall between beams. When a mesh deck is installed, the goods will remain safe. This reduces workplace accidents and ensures that products are kept in good shape.

Airflow, Visibility, and the Weather

This deck design enables unrestricted airflow. Proper ventilation and fire safety are crucial in warehouses that store food or beverages, as they also simplify inventory checks.

Fire Code Compliance

Every level of storage must be sprinklered to comply with fire codes. While solid shelves can block sprinklers and prevent water from passing through, mesh loading decks help to meet fire regulations.

Versatile Storage

These decks can be used with cartons and irregularly shaped inventory. Also, they can be used for irregularly shaped products, cartons, or mixed inventory. It is therefore suitable for storing different goods in warehouses.

Easy Installation

Installing mesh decks is simple. They easily slide into beams without tools, making them user-friendly and cost-effective.

Types of Mesh load decks

Different industries require different kinds of mesh decking, and warehouse mesh decking is available in many useful types. Each type is designed to meet a specific need, and choosing the right one helps to keep products safe and stored in the best way.

- Pallet rack wire decking is the most common type, and it is used for holding pallets or boxes securely on the racks.

- Steel mesh decking is a strong and heavy-duty option, and it is chosen when extra support is needed for heavier loads.

- Long span mesh decking is used when warehouses need to store items that are very large or wide.

- Mesh deck racking installation is designed to be quick to set up, safe to use, and reliable for everyday warehouse work.

By using the right type of mesh decking, warehouses can improve safety, protect their products, and make sure that their storage system is strong and dependable.

Storage Decking Options

Decking Materials | Safety Level | Airflow | Fire Compliance | Load Support | Best Use Case |

| Solid Steel Shelves | The medium-sized apprehension | Low Cost | Low Cost | High | Heavy boxed goods |

| Wooden Boards | Low Cost | Low Cost | Low Cost | Medium | The Low-Cost Short-Term Use |

| Mesh Load Decks | High | High | High | High | Pallets, cartons, irregular goods |

Mesh load decks have the highest balance in safety, compliance, and versatility.

Where Are Mesh Decks Used?

Retail Distribution Centres

For mixed inventory, stores use wire pallet decking. This open design allows employees to easily check for items.

Manufacturing

Many factories have steel mesh decking used for their parts and products. These goods often aren’t palletised, so the mesh is a strong surface.

Food and Beverage

Food storage must have adequate air flow to maintain hygiene. Mesh decks promote ventilation to help keep food in a better state.

About the Automotive Industry

It is used by warehouses to store boxed components and accessories. Flexible for different shapes.

General Warehousing

Safety, versatility, compliance, and flexibility are important for any warehouse.

Mesh Deck Racking Installation

The installation of mesh decks is simple and effective because the employee only needs to place the deck boards directly onto the pallet racking, and this can be done without the use of special tools since the channels fit neatly and align properly. This makes pallet racking installation with mesh decks straightforward and efficient. The process is also more cost-effective compared to other systems, which is why many warehouses across Australia have decided to upgrade to mesh decking, even if they already have a pallet racking system in place.

Key points about mesh deck installation:

- Mesh decks are placed directly onto the pallet racking without extra tools.

- The channels fit neatly and stay aligned for a professional finish.

- The installation process saves time and reduces overall costs.

- Warehouses upgrade to mesh decking because it provides better safety and value.

Rack Decking Solutions for the Future

New technology and tighter safety standards continue to drive warehouse operations forward. Mesh decking remains important due to the fact that it strikes a perfect balance between safety, cost, and compliance. With the increase in automation of industries, there will be a need to have strong, durable surfaces with clear airflow.

Why Rackking Pty Ltd Mesh Load Decks?

Rackking provides rack decking that is reliable for businesses of all sizes. It offers professional installation, prompt delivery, custom warehouse designs, and quick deliveries. There are many products available, including shelving, pallet racks, cantilever shelves, and mezzanines.

FAQs

What materials are used in mesh load decks?

For pallet racking, mesh load decks made from welded steel with reinforcing channels provide durability and strength.

What are the safety requirements for mesh decks?

As mesh decks permit sprinklers to pass through to water, they comply with fire safety standards.

Do mesh decks require extensive installation?

No, you don’t need any special tools to install the mesh decks onto the pallet racking beams.