An industrial warehouse depends heavily on how well its storage systems are designed. For facilities handling heavy pallets, oversized goods, or high-volume stock, choosing the right industrial storage systems is not just about capacity. It directly affects safety, compliance, workflow efficiency, and long-term operating costs.

In Australia, warehouse managers and industrial business owners must also factor in strict safety and load requirements. Research consistently shows that poorly designed or overloaded racking systems increase injury risk and product damage while reducing operational efficiency.

This article is based on independent research, analysis of Australian safety standards, government publications, and guidance from industry associations. No personal installation experience, client projects, or proprietary data have been claimed.

Understanding Heavy-Duty Storage in an Industrial Warehouse

Heavy-duty warehouse storage is designed to support high load capacities, repeated forklift movement, and continuous daily use. According to Safe Work Australia, storage systems must be selected and installed based on load ratings, traffic flow, and risk exposure rather than available floor space alone. Industrial shelving systems and warehouse racking systems are engineered using reinforced steel frames, rated beams, and anchoring systems to prevent collapse or deformation under load.

This highlights why system selection and layout planning matter just as much as product quality.

Key Heavy-Duty Warehouse Storage Options

Australian warehouses use several types of heavy-duty storage solutions, each suited to specific load profiles and picking requirements:

Selective Pallet Racking

Selective pallet racking remains the most widely used system in Australia. It gives 100% access to pallets and works with most forklift types. Selective systems are ideal for mixed SKUs and fast-moving inventory where direct access is essential.

Drive-In and Drive-Through Racking

Drive-in racking allows forklifts to enter the structure, storing pallets deep within lanes. Drive in systems can increase storage density by up to 60% compared to selective racking. However, selectivity is reduced, and forklift skill requirements go up.

Double-Deep Pallet Racking

Double-deep racking stores pallets two positions deep, cutting aisle space while keeping reasonable access. This system works well where product turnover is predictable, and forklift reach capacity is sufficient.

Cantilever Racking for Heavy and Oversized Loads

Cantilever racking stores long, heavy, or irregular items such as timber, steel pipe, and sheet materials. Use cantilever systems when loads cannot be safely stored on standard pallets.

Mezzanine Storage Systems

Mezzanine systems create additional usable levels within the warehouse without expanding the building footprint. Mezzanines must be engineered to handle both static loads and live loads, like foot traffic and equipment.

Comparison of Common Heavy-Duty Storage Systems

| System Type | Pallet Access | Storage Density | Load Type | FIFO Suitable | Typical Use |

| Selective Racking | 100% direct | Moderate | Mixed pallets | Yes | General warehousing |

| Drive-In / Drive-Through | Limited | High | Uniform pallets | No | Bulk storage |

| Double-Deep Racking | Partial | High | Pallets | Limited | Medium turnover stock |

| Cantilever Racking | Direct | Moderate | Long/irregular | No | Timber, steel, pipes |

| Mezzanine Systems | Direct (manual) | High (vertical) | Cartons/equipment | Yes | Space expansion |

Compliance and Safety Requirements in Australia

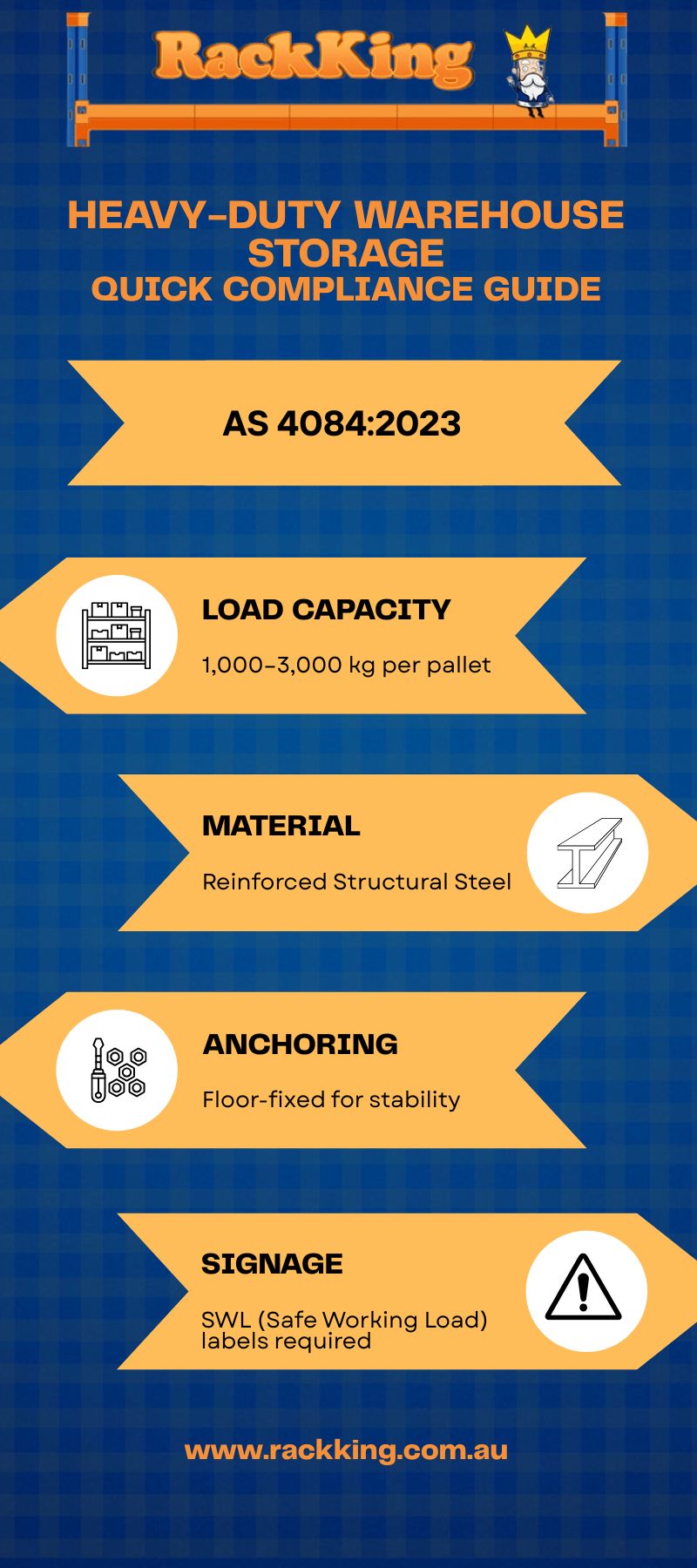

All new warehouse racking systems in Australia are expected to align with the updated AS 4084 framework. The modern standard is split into two parts:

- AS 4084.1:2023 – Design: Sets minimum requirements for the structural design of steel storage racking using recognized analysis and test methods.

- AS 4084.2:2023 – Operation and Maintenance: Covers safe operation, inspection, repair, documentation, signage, clearances, tolerances, and ongoing maintenance requirements.

Together, these parts define how racking must be engineered, installed, inspected, and maintained to minimize risk in industrial environments. The standard requires documented load ratings, formal inspection regimes performed by competent persons, and clear signage indicating load capacities. Regular in‑house visual checks combined with formal annual audits are expected as part of a compliant warehouse safety program.

Safe Work Australia further recommends routine inspections and immediate repair of damaged components to reduce structural failure risk.

Heavy-duty Warehouse Storage Quick Compliance Guide

Cost Considerations for Heavy‑Duty Storage Systems

Heavy‑duty warehouse storage costs in Australia vary by system type, load capacity, and complexity. According to All Storage Systems pricing guide, pallet rack frames and beams typically range from $175–$400+ per upright depending on height and load rating.

Factors influencing cost include:

- Load rating requirements

- Seismic and floor conditions

- Forklift compatibility

- Compliance upgrades

- Long‑term maintenance needs

Practical Guidance Based on Professional Standards

Based on guidance from Safe Work Australia, Standards Australia, and industry associations, successful heavy-duty storage planning typically includes:

Before proceeding:

- Confirm load weights and pallet dimensions using verified data

- Ensure rack design complies with AS 4084-2023

- Match forklift specifications to aisle widths and rack heights

- Plan impact protection in high-traffic zones

- Schedule regular inspections by qualified personnel

According to Work Safe Victoria, warehouses with documented inspection schedules experience significantly fewer racking-related incidents.

Conclusion

A compliant industrial warehouse storage system protects workers, reduces damage, and stabilizes operational costs. It protects workers, improves workflow efficiency, and reduces long-term operational risk. Research consistently shows that systems selected based on load data, compliance standards, and future growth outperform ad-hoc or cost-driven solutions.

For businesses seeking compliant, scalable industrial storage systems, working with established Australian suppliers like RackKing Australia ensures alignment with national standards and industry best practices.

Need Help Finding the Right Heavy-Duty Storage Solution?

Selecting the right warehouse storage system is essential for safety, compliance, and long-term efficiency. If you require reliable, heavy-duty storage that meets AS 4084-2023 standards and supports your operational objectives, RackKing Australia is here to assist.

Get expert advice and fast quotes today. Upgrade your warehouse with safe, durable, and high-capacity racking solutions.

Related Articles:

Why Racking Solutions Are Better For Warehouse Storage And Flow?

Common Rack Mistakes to Avoid for Warehouse Racking Safety

FAQs

Are warehouse racking systems required by law to meet Australian standards?

Yes. Racking systems must comply with AS 4084-2023 to ensure they can safely support intended loads. Employers are responsible for proper installation, use, and regular inspections. Safe Work NSW notes that following these standards helps prevent accidents and structural failures.

How often should industrial storage systems be inspected?

Work Safe Victoria recommends formal inspections at least every 12 months, with visual checks conducted more frequently in high-use environments.

Can existing racking be modified for heavier loads?

According to Safe Work NSW guidance, modifications should only be done by a qualified engineer or approved by the manufacturer, as changes affect load limits. Using only certified components and following safety standards is essential.