In every warehouse and storage area, it is essential to use pallet racking that complies with Australian standards and regulations. By doing so, business owners, warehouse directors, and workers will be able to reduce risk, avoid large-scale failures, and protect all employees.

These standards provide a comprehensive set of helpful guidelines to help you design the ideal pallet racking system for your warehouse.

Our simple guide provides a comprehensive overview of the requirements for pallet racks in Australia. Included are design guidelines, inspection responsibilities, and safety expectations.

What Are Australian Pallet Racking Standards?

AS 4084 Steel Storage Racking outlines the safety, strength design, and performance requirements for pallet shelving made of hot or cold-rolled steel. These standards provide information on many key components of pallet racking.

- Structural design rules

- Numbers for loading capacity and calculation

- Beam deflection limits

- Straight alignment tolerances

- Installation instructions

- Pallet rack inspection step

- Installation and use of safe products

- Proper signage and official documentation are required

This standard was developed to help ensure that pallet warehouse shelving is strong and sturdy enough to handle heavy loads.

Why Do Australian Pallet Racking Standards Matter?

Australian Pallet Racking Standards exist to protect warehouse workers, their products, the building, and themselves. Forklifts operate quickly, and pallets are very heavy. Daily work can create many opportunities for accidents. Follow pallet rack regulations to reduce risk and increase safety.

Safety Of Workers

Well-designed, sturdy racks can reduce the risk of falling objects, collisions with forklifts, and collapses. They protect workers from severe injuries and even death.

The Legal Obligations

Australia’s Work Health and Safety laws require a safe work environment. By ignoring the pallet racking requirements, you may be subject to substantial fines or be ordered to cease operations until any safety problems have been resolved.

Insurance Requirements

Many insurance companies will require that a warehouse user’s racking comply with AS 4084-2023. After an accident, insurance claims may be rejected if the racking used does not comply with AS 4084.4.

Cost Savings On a Long-Term Basis

A rack that has been designed and installed correctly will last longer. Racks with the right care and design are less likely to break and require fewer repairs.

Australian Pallet Racking Standards And Their Key Components

AS 4084 also includes important instructions on design and safety. Below is a list of important points that everyone should understand.

Pallet Racking Design Requirements

A proper pallet racking system is essential because of its importance. This is because the design must take into account the types of load and warehouse height, as well as the quality of the floor. To design a compliant system, a structural engineer must be qualified and have the necessary training.

- What type of loading and how much?

- Pallet Dimensions

- Space and distance for turning a Forklift

- Storage height and the number of levels

- There are also shaking or seismological conditions.

- Floor anchorage and strength requirements

An experienced engineer must select and measure the appropriate steel pieces, as well as the weight to support the racking system.

Beam Deflection And Straight Alignment

AS 4084 outlines rules for the amount of bending that horizontal beams are allowed to undergo when supporting heavy loads. The racking may be too heavy or not designed properly if it bends excessively. Important limits include:

- Maximum beam deflection

- Alignment and straightness tolerances

- Anchoring depth and baseplate dimensions

These limits ensure that the steel remains strong and minimizes the chances of it collapsing suddenly.

Pallet Racking Installation Standards

A correct installation is essential because even a powerful design can become unsafe when improperly constructed. Standard requires:

- Professional installers complete the installation

- Securing every upright

- Placement of beams, clips for safety, and bracing

- Proper spacing for forklifts

- Levelling the flooring surface is important for proper load distribution.

If incorrect installation occurs, there is a risk of structural failure.

Related Reading: Proper Pallet Racking Installation for Safe Warehouses- A Guide

Documentation & Signage At The Loading Area

AS 4084 demands that all rack systems display a visible and legible load indicator. The load sign on the rack must display:

- Maximum Load for Each Bay

- Maximum load at each beam level

- Rack Height

- Manufacturer or installer details

These signs are designed to warn forklift drivers of the dangers associated with overloading a structure.

Use Safely And Operate The Device

It explains how to use the standard in everyday life.

- Use of safe forklifts in proximity to racking

- Pallets – How they should be used

- Keep pallets away from beams

- Even weight distribution

- It is essential to obtain an engineer’s permission before making any changes.

These rules will help you maintain long-term stability.

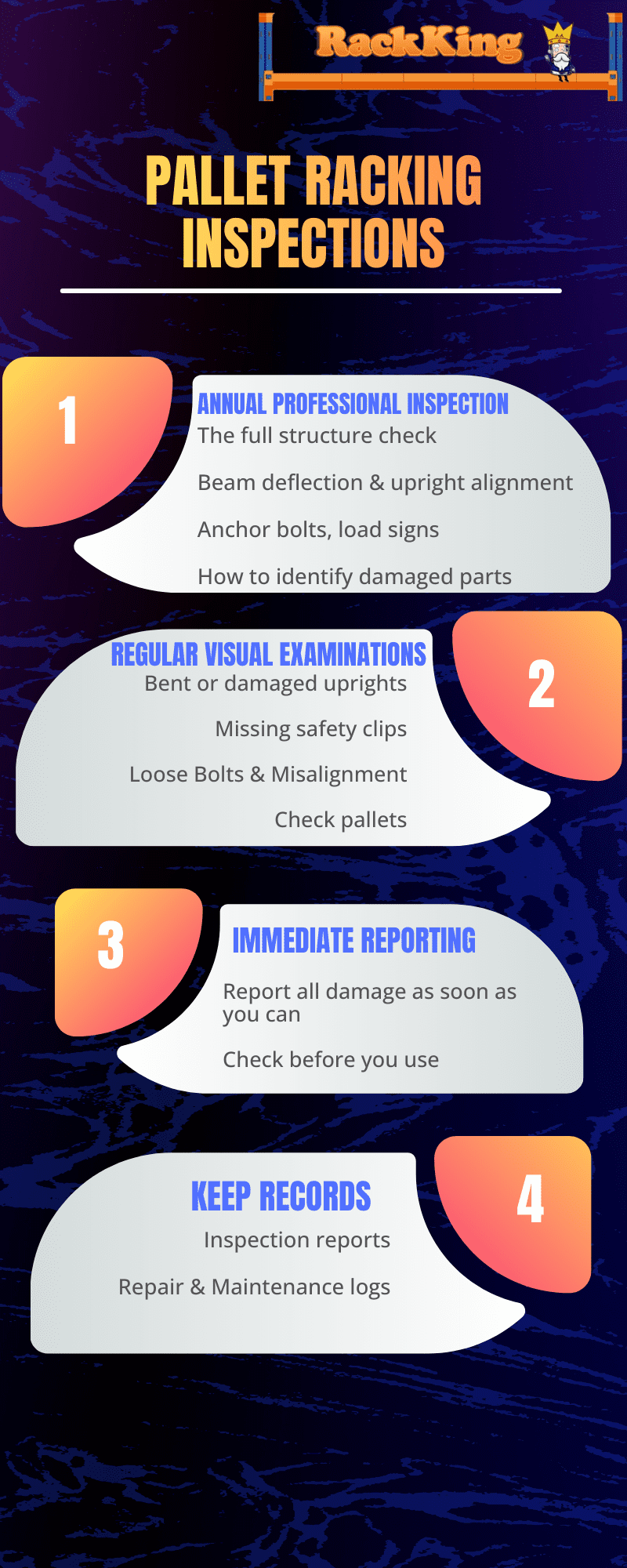

Pallet Racking Inspections Requirements In Australia

Regular pallet racking inspection will help to ensure the safety of the warehouse. AS 4084 specifies the main types and frequency of these inspections.

Annual Professional Inspection

The inspection should be performed by an engineer or trained inspector at least once per year.

- Assessment of structural integrity

- The Straightness Check

- Beam Deflection Measurements

- Anchor bolt checks

- Damage Identification

- Reload sign review

After finishing an inspection, the inspector creates a written document.

Regular In-house Visual Checks

Checks are completed by warehouse employees every week or once a month to ensure:

- Bent uprights

- Missing safety clips

- Damaged beams

- Loose bolts

- Misaligned frames

- Pallets damaged or weak

When problems are detected early, they can be prevented from growing into larger incidents.

Instant Reporting of Damage

Workers must report any damage immediately to avoid potential safety risks.

Pallet Rack Damage: Common Causes

The pallet rack may be damaged by many factors in a bustling warehouse.

Forklift impacts:

If the forklift accidentally strikes the racking while loading, unloading, or moving products, the uprights and beams may bend, twist, or shift out of their original position. This increases the likelihood of future instability.

Overloading:

Placing too much weight on shelves that they cannot support can cause beams to collapse, uprights to end and lean, and entire rack systems to be unstable.

Condition of pallets:

If they are in poor condition, this can create problems for the racking. For example, it may lead to pallets falling from their places or pallets being damaged.

Correct installation:

Racks installed incorrectly, either by not following engineering specifications or without proper instructions, may have a weaker structure, be ill-aligned, and/or inadequately attached to the floor. These factors can increase the likelihood of the racks failing during warehouse operations.

Mixed or Incompatible Pieces:

Combining elements from different manufacturers and systems could affect the alignment of components, decrease the overall strength, and hinder the performance of the rack, resulting in structural weaknesses.

A Rusty rack:

Exposure to long-term water, chemical, or humidity can cause steel parts to corrode. Rust can weaken the system and decrease its durability.

Modifications Unapproved:

A qualified engineer must approve any changes made to the racking system, including adding more levels, relocating the beams, or modifying the original layout. These modifications can compromise the system’s stability, put additional stress on its components, and create unsafe conditions for employees and equipment. It is important to understand the structural causes of problems.

Pallet Racking inspections

How To Ensure Your Warehouse Meets Australian Standards?

If the warehouse takes consistent steps to ensure safety, meeting the Australian pallet racking standard is easy.

Use Of Racking Designed By Qualified Engineers

Only the right engineering documents can make a system secure.

Use of Installers

These professionals adhere to all the rules regarding anchoring, spacing, and correct placement.

Delivery Of Load Symbols

Clear load signs help prevent accidental overloading.

Training Of The Warehouse Staff

Workers must learn how to operate forklifts safely.

Schedule Routine Inspections

A structure can be kept safe by performing daily inspections and yearly checks.

Repairing Damage As Soon As Possible

All damaged parts should be replaced as soon as possible.

Maintenance Of Documentation

You must always have access to your inspection logs and drawings.

Best Practices In Pallet Racking For Safety Over The Long Term

It is important to maintain the racks in good condition.

- Use bollards or guardrails

- Avoiding mixing components

- Keeping aisles cleared

- Storing Loads Equally

- Climbing on racks is dangerous.

- Checking pallet quality

- Make sure you have the proper lighting

These steps lower accident risks.

Conclusion

All warehouses and industrial areas should adhere to Australian pallet racking regulations as they provide detailed guidelines on the safe design, installation, usage, and maintenance of racking. The risks of racking collapses, falling pallets, and workplace injuries can be greatly reduced when business owners and warehouse personnel follow these rules.

Maintaining a stable and safe racking system requires regular professional inspections, frequent visual inspections, immediate reporting of any damage, and detailed maintenance logs. This long-term compliance with these standards enhances warehouse operations. It extends the lifetime of the shelving and ensures that all products and equipment are kept safe.

Need Help Staying Compliant?

For AS 4084–approved pallet racking, professional installation, or annual safety inspections, Rack King Australia provides fully certified solutions for every warehouse.

Get quick quotes, expert guidance, and compliant racking designed to keep your workplace safe.

FAQs

Are Australian Pallet Racking Standards Mandatory?

AS 4084 doesn’t have the force of law but is still important because it specifies safe system requirements.

How Frequently Is Pallet Racking Inspected?

It is mandatory to have a professional inspect the equipment annually, with workers performing weekly or monthly checks.

Can Damaged Racking components be repaired?

An approved engineer must repair damaged components.

If the rack is loaded Too High, what happens?

In addition to bending, structural stress can also be caused by overloading.

Does It Require An Engineer To Make Changes to Pallet Racking?

For safety purposes, all changes must be approved and documented by a qualified professional in the field of engineering.